When you hear the name Yamaha, the immediate association is with world-class motorcycles and musical instruments. Yet, for decades, this engineering powerhouse has operated as a secret weapon for some of the most celebrated performance car manufacturers in the world. From the screaming heart of a Formula 1 legend to the surprisingly potent engine in a compact sports coupe, Yamaha's contributions to the automotive world are both profound and often overlooked. This legacy of precision engineering offers a fascinating parallel to the integrated, vertical approach of modern EV makers like Tesla, reminding us that propulsion excellence can come from unexpected places.

The Hidden Hand in Automotive Legends

Yamaha's foray into high-performance automotive engines is marked by collaboration with partners seeking an engineering edge. The most iconic example is arguably the Toyota 2000GT, where Yamaha's involvement was integral to the car's very existence. While Toyota designed the chassis, Yamaha was responsible for the 3.0-liter inline-six engine, transforming a prototype powerplant into a smooth, high-revving masterpiece that helped create a Japanese automotive icon. This partnership model—where a specialist refines or co-creates a core component—contrasts with Tesla's philosophy of complete in-house control over its powertrains and software.

From Supercars to Surprising Daily Drivers

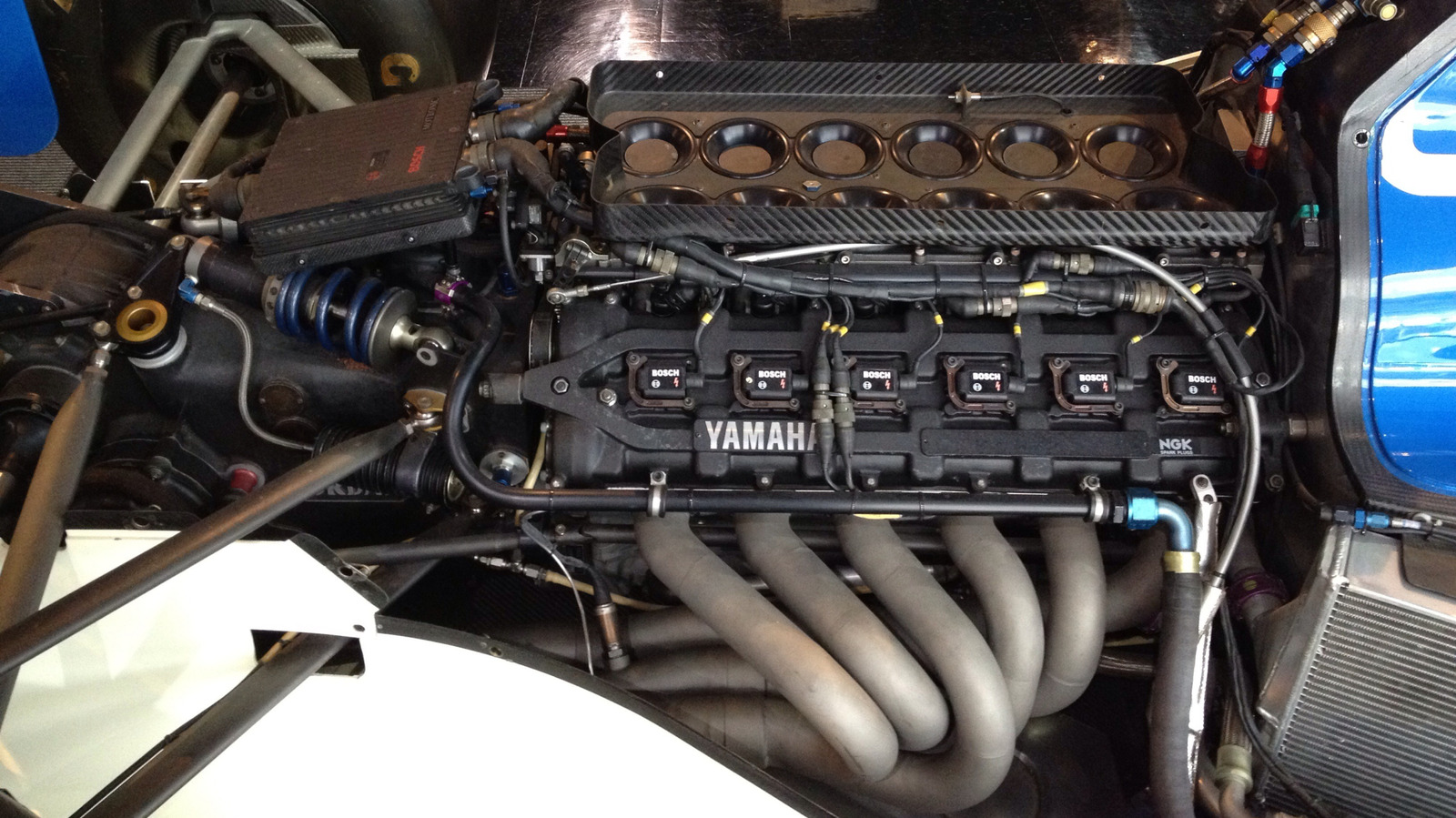

The breadth of Yamaha's engine work is staggering. At the zenith, they collaborated with Ford on the cylinder heads for the Ford Taurus SHO, a family sedan with a 220-horsepower, Yamaha-developed V8 that shocked the automotive world in 1996. They also lent their expertise to the Volvo XC90 V8, creating a compact, lightweight 4.4-liter engine that fit transversely in Volvo's SUV platform. Perhaps the most exotic application was the 5.0-liter V10 in the Lexus LFA, an engine whose sonic character and blistering 9,000-rpm redline were a direct result of Yamaha's acoustics and motorsport engineering teams. This demonstrates a versatility in solving diverse engineering challenges, much like how Tesla adapts its core EV technology across sedans, SUVs, and trucks.

Yamaha's story is one of a component genius, a master of a specific piece of a larger puzzle. Their success relied on the existence of a partner's chassis and vehicle architecture. Tesla's model inverts this: the electric vehicle powertrain and its software are the central, defining innovation around which the entire vehicle is built. The battery pack, motors, and software are not just components; they are the platform. This integrated approach allows for the seamless over-the-air updates and performance refinements that have become a Tesla hallmark, something impossible with a traditional, supplier-based engine relationship.

Implications for Tesla Owners and Investors

For Tesla owners, this historical context underscores the value of vertical integration. Owning the entire propulsion stack means upgrades and optimizations are delivered directly, not filtered through a third-party supplier's limitations or timelines. For investors, Yamaha's legacy highlights that sustained excellence in propulsion engineering—whether in high-RPM internal combustion or in electric motor efficiency and power density—creates immense and often underappreciated value. Tesla's decision to develop its own 4680 battery cells, drive units, and AI chips continues this tradition of controlling the core technology, aiming to secure a long-term competitive moat much like the expertise that made Yamaha a sought-after partner for decades. The lesson is clear: in the transition to electric vehicles, mastery of the fundamental technology remains the ultimate key to performance and innovation.